Accurate Chemical Composition and Black Mass Testing

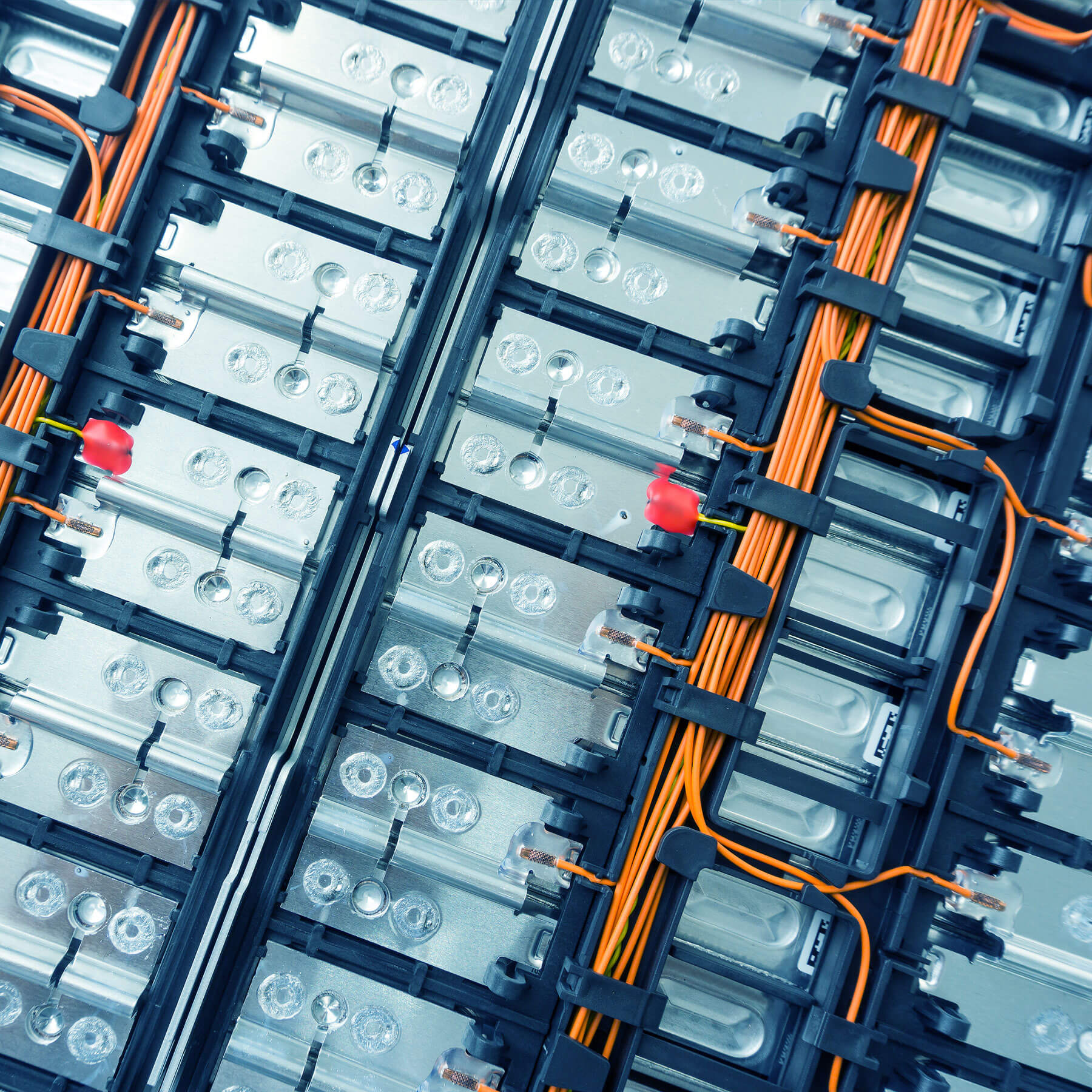

Another major area NSL Analytical is supporting the growth in Lithium-ion battery material testing is in the chemistry of recycled materials known as black mass. This is one of the most important issues relating to the circular economy for electrification.

Lithium-ion batteries include metals such as nickel, cobalt, iron, manganese, copper and lithium. Once they pass the end of their useful life, they can be shredded and turned into black mass, so-called because of the typical color owing to graphite from the anodes.

The content of the metals in black mass varies by source. NSL Analytical provides industry leading accuracy and turnaround times to recyclers to confirm the chemical composition and weight percentages of the valuable elements quickly to run their businesses efficiently.

NSL Analytical is a member of NATTbatt International. You can learn more about NATTbatt on their website.

Here’s Where We Can Help:

Chemical Analysis

NSL offers bulk and trace level analysis of black mass and all battery materials during all parts of the battery lifecycle – from R&D studies and process development to production quality control and recycling.

We specialize in trace analysis techniques such as ICP-OES, ICP-MS, and DC-Arc to test for impurities, contaminants and elemental migration after cycling (such as changes in lithium and manganese content in cathodes). Our team applies chemical composition testing techniques such as X-Ray Fluorescence Spectroscopy (XRF), X-Ray Diffraction (XRD), Spark-OES, UV-Vis Spectroscopy and classic wet chemistry methods to a wide range of material matrices. We use Ion Chromatography to analyze for electrolytic anions such as halogens, sulfates and carbonates.

Particle Size Analysis

We can also test the particle size distribution of powder materials used in electrodes and solid electrolytes with techniques such as sieve analysis or laser diffraction. Laser diffraction analysis can be carried out on either wet- or dry-dispersed samples down to submicron resolution.

BET Surface Area & Porosity Analysis

NSL uses Gas adsorption to characterize the surface and porosity of solid materials used for electrodes and solid electrolytes. We use Krypton BET for low surface area (<1 m2/g) electrode materials, such as NCA, LCO, etc. And, we use Nitrogen BET for moderate surface area (>1 m2/g) electrode materials, such as LFP, LTO and graphite, as well as high surface area (>1,000 m2/g) materials such as activated carbon.

Powder & Material Density

We can perform precise density testing on both powder battery materials and solid battery components. We can test Apparent, Bulk and Tap Density of powders by several volumetric and gravimetric methods. Plus, we can test Solid density by Archimedes water displacement or helium gas pycnometry. And we test Skeletal/True Density of powders or solids by helium gas pycnometry.

Thermal Analysis

NSL performs Thermogravimetric Analysis (TGA) and Differential Scanning Calorimetry (DSC) of polymer and polymer-ceramic composite battery materials used as electrode binders, charge separators and solid electrolytes. We can obtain a wide range of stability and decomposition information from thermal analysis, including glass transition temperature and the melting point of polymers.

Moisture Analysis

Karl Fischer titration is the gold standard for moisture analysis.

Using either volumetric or coulometric titration methods, the technique can quantify the water content of materials from ppm-levels up to 100%. We titrate non-reactive, soluble solids and liquid samples directly, while analyzing reactive materials after treating the sample to suppress interfering reactions.

Additionally, NSL employs the Oven Desorption variant of Karl Fischer titration to analyze insoluble solids (such as metal powders) or materials like salts that only release water at high temperatures.

Microscopy and Elemental Mapping

NSL’s expertise in optical and electron microscopy provides high resolution structural analysis of nearly any battery material, including layered materials. We use Scanning Electron Microscopy (SEM) with Energy Dispersive X-Ray Spectroscopy (EDS/EDX) to conduct elemental mapping of the distributions and migration of elements before and after cycling.