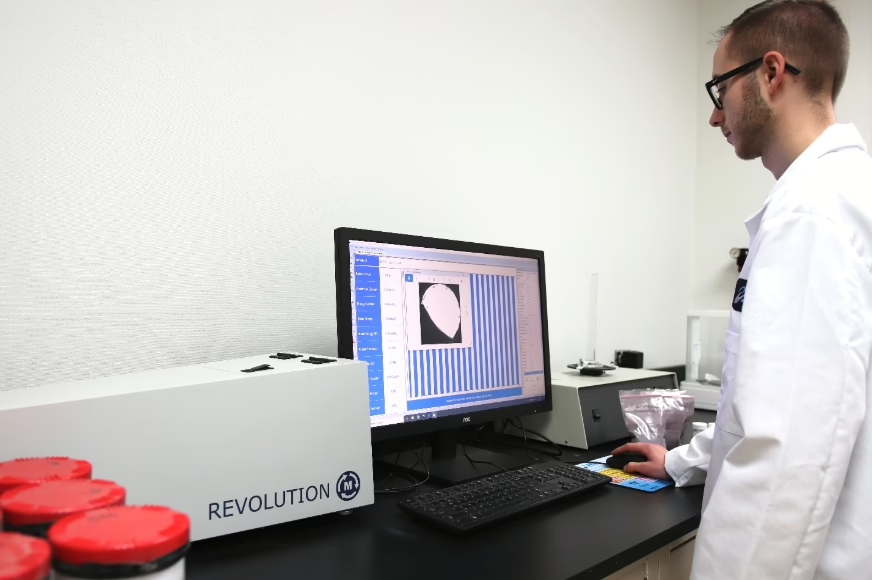

On October 6, 2025, NSL’s Dr. Ross Cunningham presented at the ASTM International Conference on Advanced Manufacturing (ICAM) in Las Vegas. Dr. Cunningham joined more than 1,100 scientists, engineers and industry leaders from 35 countries who attended the flagship event for additive and advanced manufacturing. Below is a summary of Dr. Cunningham’s presentation. The…