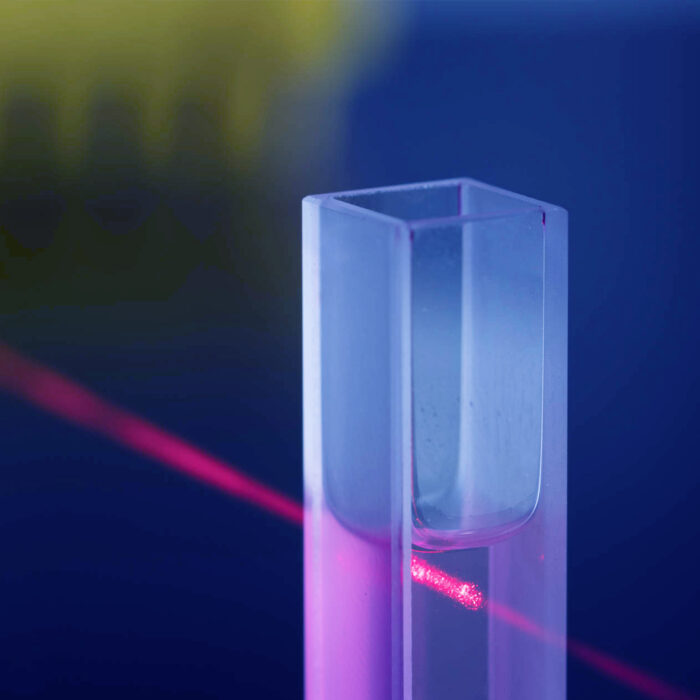

Consulting Services

Our materials evaluation consulting services utilize the analytical testing capabilities of our materials testing lab with the technical skills of our metallurgists and chemists.

Materials Evaluation Consulting Services

Not all material quality problems are the result of material properties. Sometimes, external factors cause materials to fail. Our consulting services utilize the analytical testing capabilities of our testing labs along with the technical skills of our metallurgists and chemists to help customers identify and troubleshoot problem areas beyond materials testing.

Our technical expertise includes inorganic and polymer chemists, metallurgists, material engineers, and retained consultants available to assist you from design to production offering consulting services such as:

- Problem Identification

- Materials Selection

- Process Assessments

- Product Evaluations

- Inspection and Certification

- Research and Feasibility Testing

- Method Development and Selection

- Designed Experiment Evaluation

- Failure Analysis

- Laboratory Audits

- Instrumentation Certification

- Training

- Expert Witness

As an Independent Testing Laboratory, NSL Analytical can also provide objective third-party analysis of your laboratory, provide recommendations, and certify your laboratory instrumentation and procedures.