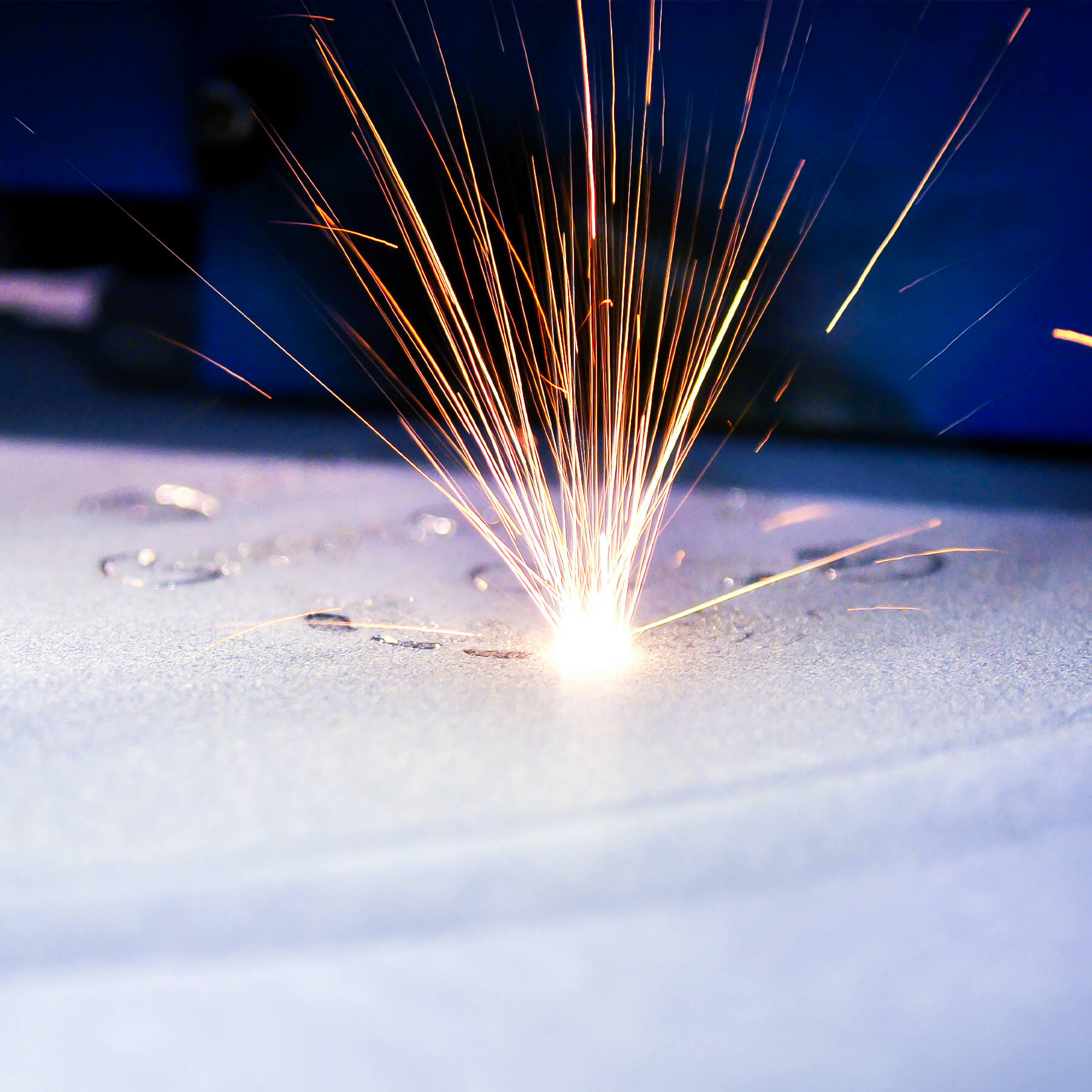

Leaders in Metal Additive Manufacturing Testing

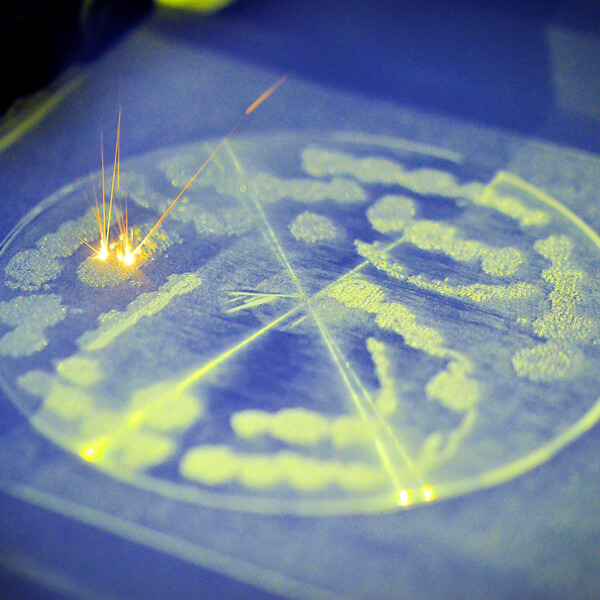

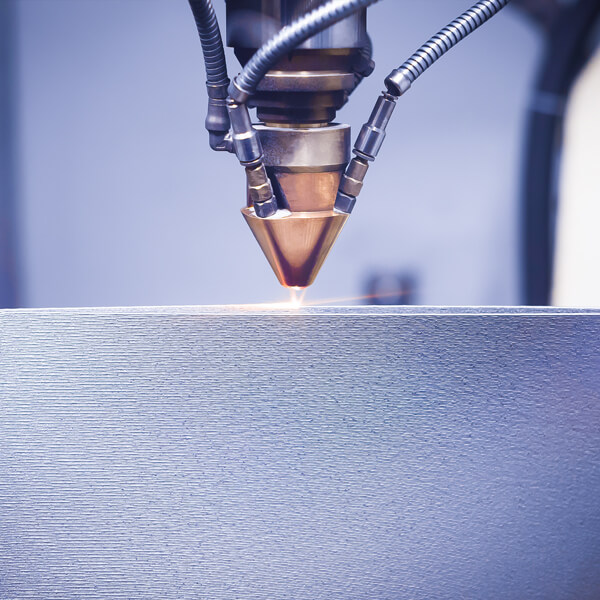

Metal additive manufacturing productivity has improved by orders of magnitude in its 2+ decades of industrial use. It is going through an exponential development cycle with myriad new alloy development approaches coupled with exciting new process improvements.

Taken together a new phase of industrial application expansion of its use is happening. The key to unlocking this potential is increasing the confidence and speed of deployment for new process and alloy combinations. The foundation for doing that is creation of salient materials data sets that inform the use of AM printed metals for specific applications.

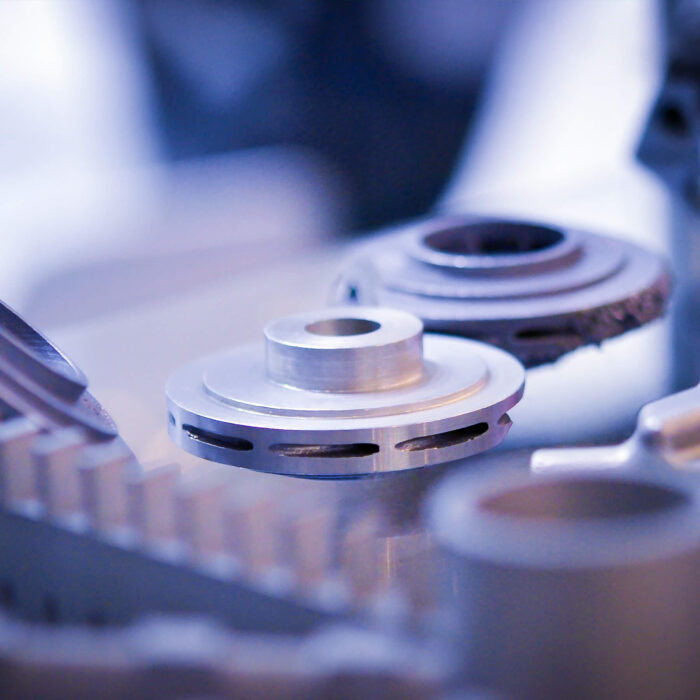

Nearly 10 years ago NSL began investing to support what at the time was a nascent, yet exciting industry. This started with our foundation of chemistry testing using mass spectroscopy and other techniques like LECO and XRF, then grew with a fully capable physical properties of metal powder characterization lab, and now integrates microscopy, metallography, and mechanical testing with chemistry, physical metallurgy, and additive process thought leaders across our business.

Today, NSL is a world leader in testing for industrial metal AM powder feedstock and components and is deeply invested in growing this exciting community of practice. We have extensive capabilities ranging from alloy chemistry, to powder, to characterization, to mechanical testing.