Wide Breadth of Ophthalmic Testing Capabilities

Our expert Ophthalmic Testing capabilities include:

- Lens and frame testing

- Photochromic testing

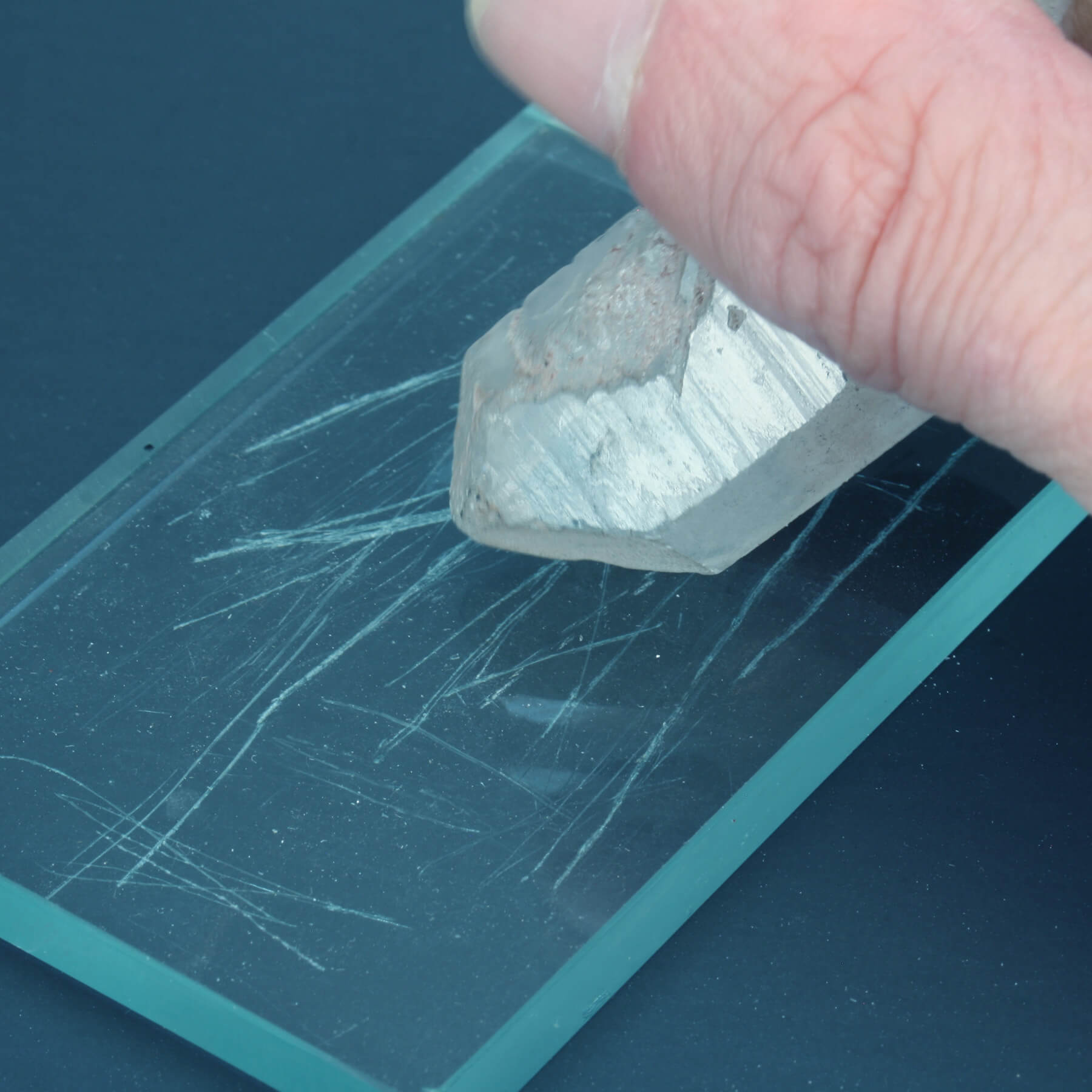

- Abrasion testing

- Coating testing

- Smulated exposure testing (ESWT)

- Polarization

- Plus strength and optical properties

Lens tests, based on the ANSI Z80.1-2010 standard, include testing for Anti-Reflective Coating, Durability (ISO 8980 Part 4); and Hard Coat Abrasion Resistance (ISO 8980 Part 5).

NSL Analytical also tests Frames and Accessories which are subject to regulatory standards (EU Nickel Release, CPSIA and CA Prop 65).