Ceramics Analysis

Examples of analyses include:

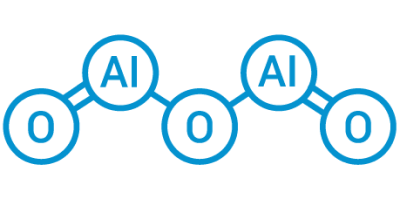

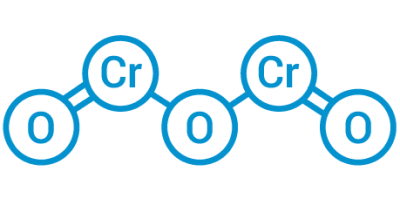

- Bulk Analysis (%): SiO2, Al2O3, ZrO2, CaO, K2O, Na2O, MgO, MnO, Fe2O3, P2O5, ZnO, Cr2O3, TiO2, HfO2

- Trace Analysis (ppm): Na, Mg, Al, Si, K, Ca, Ti, Fe, Zn, Se, Zr, Ag, Sn, Sb, Pb, Bi

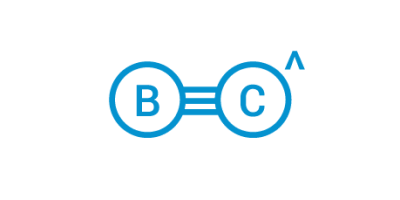

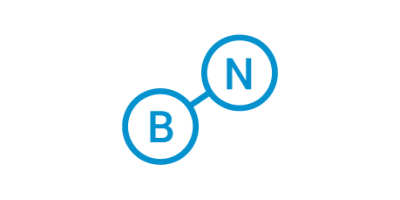

Advanced ceramics consist of metallic oxides, carbides, and nitrides that provide excellent hardness and resistance to high temperatures, wear, and corrosion. They are usually made by mixing powdered minerals with certain chemicals, followed by shaping and heating to form the part. They function as components in electronics, armor, cutting tools, jet engines, medical devices, heat exchangers, and many other products.

Examples of analyses include: