Organic Polymers

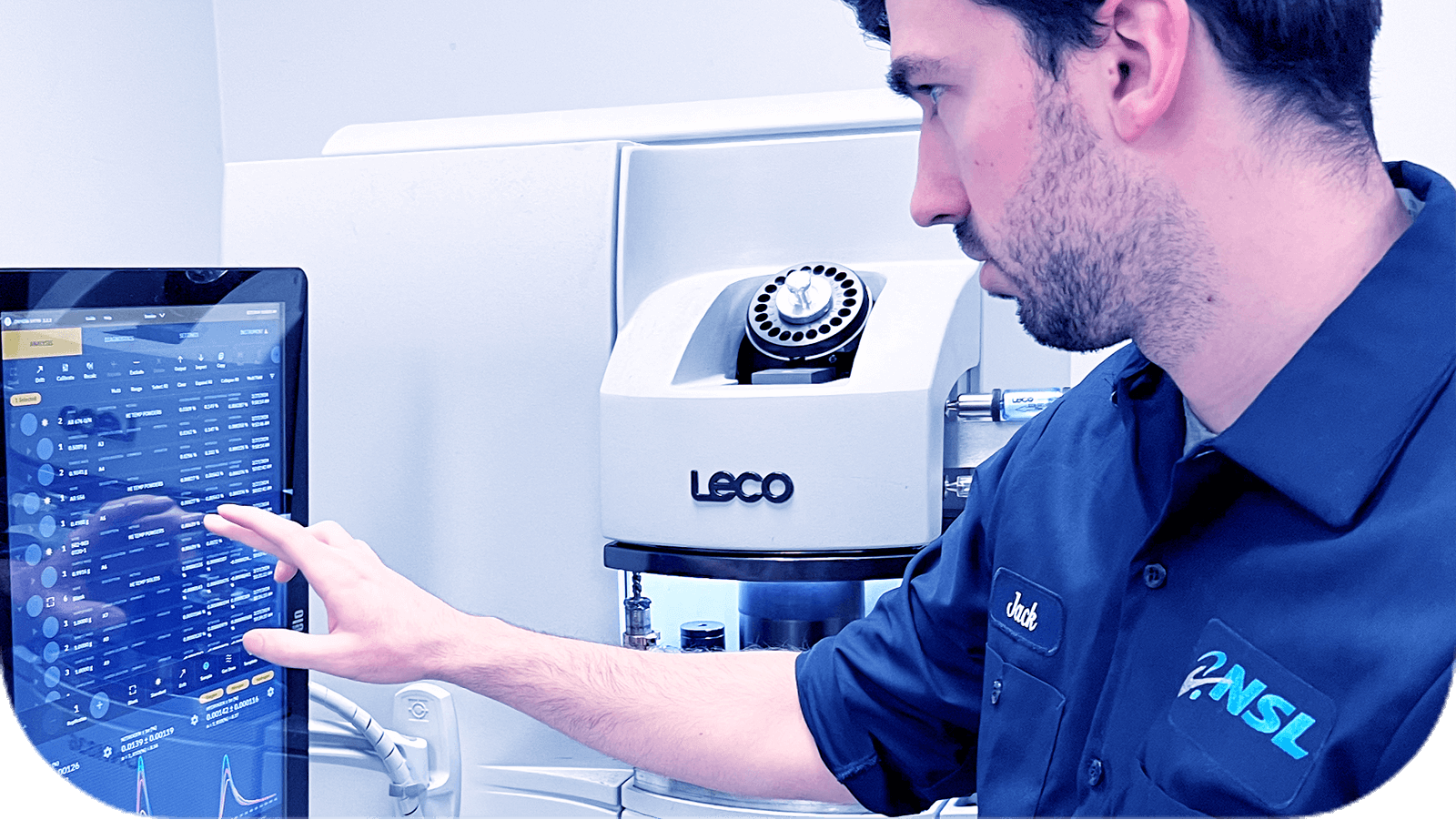

Rely on NSL Analytical’s team of experienced specialists for organic polymers testing for mechanical properties and capabilities to analyze failed parts.

Organic Polymers Testing

Polymers are high-molecular-weight organic compounds formed by long chains of simple molecules called monomers on a backbone of carbon atoms. Polymers are classified as thermosets or thermoplastics. Thermosets are polymer resins that form permanent shapes when heated because chemical crosslinks form between chains. Thermoplastics, on the other hand, can be repeatedly shaped and melted, as no chemical crosslinking takes place.

Polymer Testing Expertise

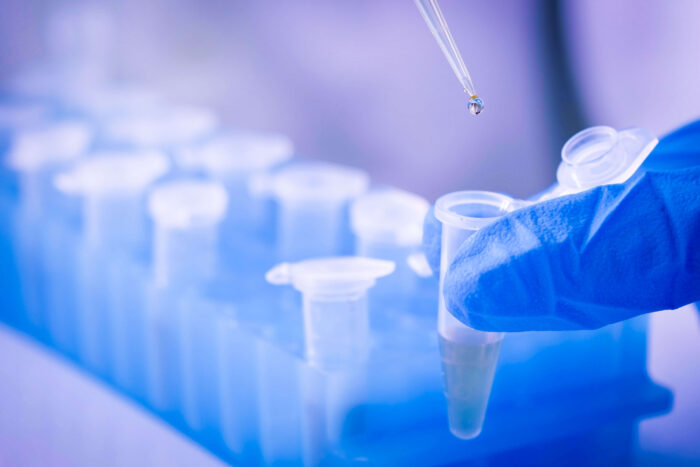

NSL Analytical’s experienced team of polymer specialists knows that the typical polymer part is much more complex than a simple thermoset or thermoplastic. Virtually every polymer product also contains fillers, binders, plasticizers, fire retardants, and other additives, and is also very likely to be alloyed with other polymers. In many cases, polymers serve as the matrix material for composites, and may be reinforced with fibers of carbon, glass, or metal – or with particles of ceramic, metal, carbon, or other materials.

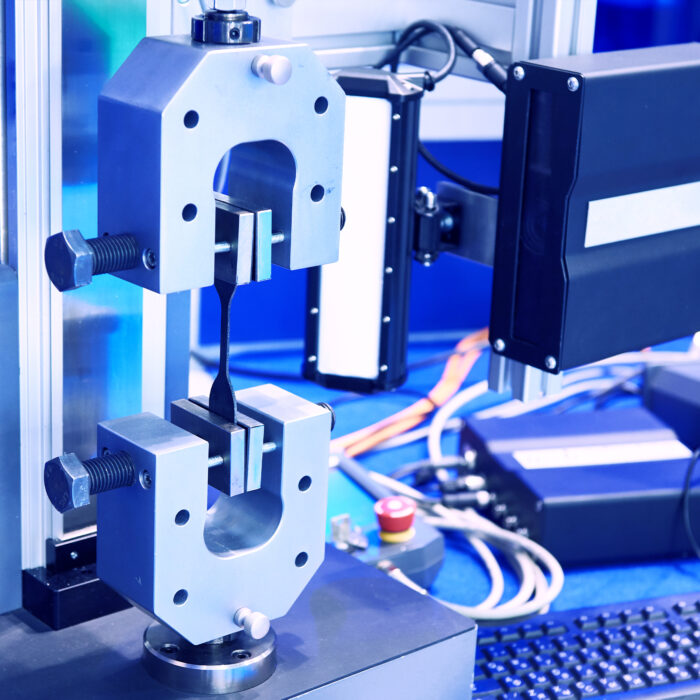

These specialties use a variety of sensitive analytical instruments and techniques to determine physical and chemical characteristics of materials, including the detection of restricted chemicals such as phthalate plasticizers and brominated fire retardants (PBB and PBDE.) They test for mechanical properties such as strength and stiffness, and for physical characteristics such as melting point and crystallization temperature. They can also provide elemental analyses to determine that the polymers do not contain mercury, nickel, lead, or other restricted elements.

The depth of the team’s experience also enables them to analyze failed parts to find the root cause of failure; and to reverse-engineer products to determine not only the constituent materials, but also how parts were fabricated.